Here’s how our latest Centre of Excellence benefitted from CleanLight

The Problem

This busy office contains not just administrative staff but also needs to accommodate staff from both the trade counter and fulfilment warehouse. This constant heavy footfall means that social distancing is impractical. In a business heavily reliant on the manual processing of orders, the potential for cross-transmission of airborne illnesses, such as influenza and COVID-19 is very high. The potential loss of productivity is therefore significant.

The area had limited provision for mechanical air handling other than the ability open external windows and doors. With the room in constant use, there was minimal scope for managing poor air quality or increased CO2 levels.

This was evident in the CO2 level readings and bacteria collections carried out during the “before” phase of the Air Quality Audit. Throughout the testing period, CO2 levels were close to or in excess of 2000 ppm. The HSE states, “CO2 levels consistently higher than 1500ppm in an occupied room indicate poor ventilation and you should take action to improve it.”

The Solution

Following the completion of the Air Quality Audit, a lighting design was created that replaced the existing lighting configuration ensuring lighting levels were delivered in line with CIBSE guidelines. This ensured consistent coverage of CleanLight panels that Lightico were calculated to deliver the equivalent of 8.81 ACH (air changes per hour) in excess of the recommended 5 ACH.

Through the simple replacement of the existing lighting, the CleanLight panels are now providing clean air without the need for the business to invest in installing and operating mechanical ventilation.

The Results

Following the installation of CleanLight the “after” stage of the Air Quality Audit was completed. From this, a significant improvement in air quality was identified when measuring both CO2 levels and bacteria counts. This will not only reduce the potential risk of the transmission of airborne pathogens but also means that the business will no longer need to act on high levels of CO2 causing short-term impact on productivity.

By not being forced to install mechanical air handling to maintain air quality the business has saved both a significant, upfront capital investment and an increase in operating costs and carbon emissions.

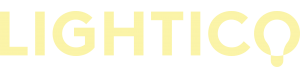

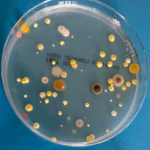

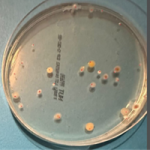

Number of colony forming units identified after 72hr incubation:

Plate location | Bacterial colony count (per plate) – CFU | ||||

Before Cleanlight | Before Cleanlight | After Cleanlight | After Cleanlight | ||

CFU | CFU/m3 | CFU | CFU/m3 | % Diff | |

Location 1 | 70 | 743 | 26 | 276 | -63% |

Location 2 | 58 | 615 | 38 | 403 | -35% |

Location 3 | 74 | 785 | 21 | 223 | -72% |

Location 4 | 33 | 350 | 14 | 149 | -58% |

Site Average | 59 | 623 | 25 | 263 | -58% |

As a Greentech distributor within Edmundson Electrical we were keen to understand better how Lightico’s CleanLight could support our customers in increasing their energy efficiency and reducing their carbon footprint. After seeing the improvement in air quality just by changing the lights and without increased HVAC. We would recommend all our customers consider CleanLight as part of their NET ZERO strategy.

Adrian Wild

Profit Center Manager,

Edmundson Electrical Lincoln

The Bigger Picture

Through the simple replacement of the existing lighting, the CleanLight panels are now providing clean air without the need for the business to invest in installing and operating mechanical ventilation.