CleanLight is a revolutionary LED panel that effectively destroys viruses and bacteria, including COVID-19, in the air. Endorsed by renowned microbiologist Dr Carl Edwards and rigorously tested in both laboratory and real-world settings, CleanLight effectively eliminates bacteria, viruses, pollutants, and odours in indoor environments.

Our Air Quality Audit is a precise, scientifically validated process that identifies potential sources of airborne pathogens and pinpoints where disease transmission is most likely to occur.

CEF Heathrow North became a member of the Lightico Center of Excellence program in May 2022, which includes an Air Quality Audit and CleanLight installation to showcase the benefits to staff and customers. Located on the bustling M4 corridor, the Heathrow North branch serves hundreds of customers daily.

The challenge

At an electrical wholesale branch, managing air quality and preventing the spread of airborne diseases presents a unique set of challenges. The trade counter area, which is open to the public, and the sales office, where staff from the warehouse and counter congregate, both pose a high risk of airborne illness transmission to staff, with the potential to significantly impact productivity and service levels.

The branch had limited options for mechanical air handling, with the only available solution being the ability to open external windows and doors. This made it difficult to manage poor air quality and increased CO2 levels in the constantly-used space.

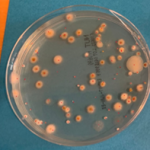

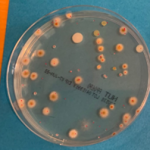

During the “before” phase of the Air Quality Audit, CO2 levels averaged 1,400 ppm. This is considered poor ventilation according to the HSE, which states that “CO2 levels consistently higher than 1500ppm in an occupied room indicate poor ventilation and you should take action to improve it.” Additionally, airborne bacteria levels were measured at over 500 CFU/m3 throughout the branch, exceeding the European Commission’s permissible limit of 500 CFU/m3 for non-industrial premises.

The solution

A lighting design was developed that adheres to CIBSE guidelines for optimal working light levels. Additionally, the design strategically placed CleanLight panels, which Lightico calculated to deliver the equivalent of 6.77 ACH (air changes per hour), surpassing the recommended 5 ACH by CIBSE.

By simply replacing the existing lighting, the CleanLight panels are now effectively purifying the air without the need for costly mechanical ventilation systems to be installed and operated. This solution not only improves the indoor air quality but also provides energy-efficient lighting. Overall, the implementation of CleanLight panels not only results in a cleaner and healthier indoor environment but also provides a cost-effective solution to improve indoor air quality.

“The Centre of Excellence programme is a great way for us as a branch to understand the benefits that CleanLight delivers because we can see it for ourselves every day. To have a live example of how the product can reduce CO2 levels and provide a visible difference to air quality is so powerful when presenting CleanLight to our customers.”

Arran Scott — Branch Manager, CEF Heathrow North

The results

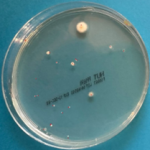

After installing CleanLight, an Air Quality Audit was conducted to measure the impact on the indoor air quality. The results showed a significant improvement in both CO2 levels and bacteria counts, indicating a reduction in the potential risk of airborne pathogen transmission. This not only benefits the health and safety of the staff but also eliminates the need for costly mechanical air handling systems to maintain air quality, which had a short-term impact on productivity. The implementation of CleanLight also provided significant cost savings for the business, as they no longer needed to make a large upfront capital investment and ongoing operating costs associated with mechanical air handling systems. Additionally, it reduces the carbon emissions that are associated with mechanical air handling systems.

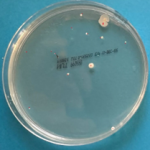

Plate location | Bacterial colony count (per plate) – CFU |

| |||

Before Cleanlight | Before Cleanlight | After Cleanlight | After Cleanlight |

| |

CFU | CFU/m3 | CFU | CFU/m3 | % Diff | |

Location 1 | 53 | 562 | 22 | 233 | -58% |

Location 2 | 62 | 658 | 13 | 138 | -79% |

Location 3 | 97 | 1029 | 21 | 223 | -78% |

Location 4 | 38 | 403 | 15 | 159 | -60% |

Average across the location | 63 | 663 | 15 | 188 | -71% |

According to the sanitary standards of the European Commission for non-industrial premises, the permissible limits of bacterial load is ≤ 500 CFU/m3. By reducing the level of CFU to 188 CleanLight has enabled the branch to adhere to these standards.

The bigger picture

CleanLight from Lightico offers a comprehensive solution to improve indoor air quality and protect your staff from potential health hazards, without compromising their work or adding extra protocols and processes. The process begins with a thorough Air Quality Audit to identify areas of concern. Once identified, CleanLight LEDs can be quickly installed and immediately begin eliminating airborne bacteria, viruses, pollutants, and odours, using only light. This non-intrusive, instantaneous, and highly effective solution ensures the protection of your staff and customers.

By switching to CleanLight, you can elevate your indoor air quality and safety with minimal disruption and no additional energy costs.