As part of our Centre of Excellence programme, we installed CleanLight at Rexel’s busy distribution office in Leeds.

The Challenge

This busy office contains not just administrative staff but also needs to accommodate staff from both the trade counter and fulfilment warehouse. This constant heavy footfall means that social distancing is impractical. In a business heavily reliable in the manual processing of orders, the potential for cross-transmission of airborne illnesses, such as influenza and COVID-19 is very high. The potential loss of productivity is therefore significant.

The area had no provision for mechanical air handling with no fresh air intake or extraction installed. With the room in constant use and no windows, there was no solution for managing poor air quality or increased CO2 levels.

This was evident in the CO2 level readings and bacteria collections carried out during the “before” phase of the Air Quality Audit. Throughout the testing period, CO2 levels were in excess of 1500ppm. The HSE states that ”CO2 levels consistently higher than 1500ppm in an occupied room indicate poor ventilation and you should take action to improve it.”

The Solution

Following the completion of the Air Quality Audit, a lighting design was created that replaced the existing lighting configuration ensuring lighting levels were delivered inline with CIBSE guidelines. This ensured consistent coverage of CleanLight panels that Lightico calculated to deliver the equivalent of 7.32 ACH (air changes per hour).

Through the simple replacement of the existing lighting, the CleanLight panels are now providing clean air without the need for the business to invest in installing and operating mechanical ventilation.

“We are delighted with the results of this case study! At Rexel Lighting Solutions we pride ourselves on being at the forefront of new and emerging technologies and these results prove that Lightico has a fantastic innovative product that WORKS! It’s great to be working in partnership with Lightico to bring this technology to market to help keep both our Rexel colleagues and their customers safe and healthy”

Steve Britton — New Product Development Manager, Rexel UK

The Results

Following the installation of CleanLight the “after” stage of the Air Quality Audit was completed. From this a significant improvement in air quality was identified when measuring both CO2 level and bacteria counts. This not only will reduce the potential risk of the transmission of airborne pathogens but also means that the business will no longer need to act on high levels of CO2 causing short term impact to productivity.

By not being forced to install mechanical air handing to maintain air quality the business has saved both a large, upfront capital investment as well as an increase in operating costs and carbon emissions.

|

Plate location |

Bacterial colony count (per plate) – CFU |

||||

|

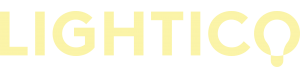

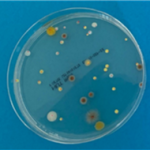

Before Cleanlight |

Before Cleanlight |

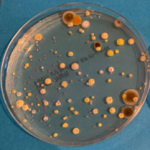

After Cleanlight |

After Cleanlight |

||

|

CFU |

CFU/m3 |

CFU |

CFU/m3 |

% Diff |

|

|

Position 1 |

60 |

637 |

38 |

403 |

37% |

|

Position 2 |

87 |

923 |

40 |

424 |

54% |

|

Position 3 |

201 |

2,133 |

51 |

541 |

75% |

|

Position 4 |

102 |

1,082 |

70 |

743 |

31% |

|

Position 5 |

117 |

1,242 |

35 |

371 |

70% |

|

Site Average |

113 |

1,203 |

47 |

497 |

59% |

Bacteria collected after CleanLight was installed are now below WHO contamination levels. CO2 levels were also on average, 59% lower.

|

Time |

Fixed CO2 Monitor |

|

|

Before CleanLight |

After CleanLight |

|

|

Start |

1,547ppm |

642ppm |

|

15 mins |

1,522ppm |

685ppm |

|

30 mins |

1,571ppm |

667ppm |

|

45 mins |

1,603ppm |

685ppm |

|

60 mins |

1,628ppm |

551ppm |

|

Site Average |

1,574ppm |

646pm |